How the Mining Industry Uses Sediment Sampling Data

In mining, the decisions made before the first shovel hits the ground can determine the success or failure of an entire operation. Sediment sampling is one of the earliest steps taken in site assessment, but the real value doesn’t come from collecting samples. It comes from understanding what the data reveals. Explore how the mining industry uses sediment sampling data.

Pre-Extraction Site Analysis

Before physical extraction begins, mining operators rely on sediment sampling data to evaluate a site’s mineral potential. By examining sediment layers in streams, rivers, or soil beds, geologists can detect the presence of target materials such as gold, copper, or rare earth elements. Concentrations of these materials in fine sediment can serve as reliable indicators of larger deposits upstream or within nearby bedrock formations.

This type of analysis also reveals patterns of mineral dispersion, which informs where exploratory drilling should be focused. For example, if elevated concentrations are found within a 500-meter radius of a proposed drilling location, that area may be prioritized for immediate follow-up. Data-driven targeting prevents unnecessary drilling and reduces the environmental footprint during early-stage exploration.

Baseline Environmental Assessments

Most regulatory frameworks require a baseline environmental assessment before developing a mining site. Sediment sampling plays a central role in this phase, offering insight into the existing chemical and physical makeup of the surrounding environment, particularly within nearby waterways, wetlands, or sediment beds.

The goal is to obtain an accurate snapshot of current conditions, measuring sediment composition, background pollutant levels, and the presence of metals or hydrocarbons already in the environment. The data is used to develop site-specific environmental management plans.

For instance, if the baseline shows naturally elevated levels of manganese in sediment, that can be accounted for during post-mining comparisons. Without this baseline, mining companies risk being held accountable for pollutants that were present long before activity began. Establishing this record ensures a fair standard for regulators, communities, and operators.

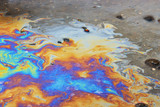

Water Contamination Risk Evaluation

Mining sites near water sources may have a high risk of contaminant migration. This is important in operations involving acid-generating rock, tailings ponds, or heavy machinery near surface water. Sampling reveals the presence and movement of arsenic, selenium, and cadmium, which have specific thresholds established by environmental agencies.

If sampling in sediment from a downstream catchment area reveals arsenic levels exceeding 10 ppb, that may trigger the need for mitigation measures before further development. Engineering teams use this data to design drainage systems, control sediment displacement, and reduce leaching into groundwater or nearby ecosystems. Addressing these issues proactively helps projects avoid regulatory delays and environmental harm.

Regulatory Compliance and Reporting

Sediment data is essential in permit acquisition and ongoing regulatory compliance. In the United States, the Environmental Protection Agency (EPA) and state-level departments of natural resources require sediment monitoring as part of a National Pollutant Discharge Elimination System (NPDES) permit or similar regulatory framework. Reports may need to be submitted quarterly or semi-annually, depending on the size and location of the operation.

To meet these obligations, mining companies must gather data from consistent sampling points, document collection methods, and maintain a chain of custody for all lab results. Failure to provide documentation can result in delays, fines, or the suspension of operations. In regions where local communities are involved in oversight, publishing this data can also support transparency initiatives and build trust with stakeholders.

Operational Adjustments Based on Trends

Sediment sampling doesn’t stop once excavation begins. In fact, ongoing data collection allows operators to detect emerging trends that may demand operational changes. Shifts in sediment chemistry, such as increasing concentrations of sulfates, heavy metals, or total suspended solids, can signal runoff issues, containment failures, or equipment inefficiencies.

Instead of reacting to problems after they worsen, mining teams use long-term sediment data to refine their strategies in real time. This may involve modifying material handling procedures, adding silt curtains or filter berms, or upgrading on-site water treatment systems. These adjustments maintain permit compliance while minimizing the risk of costly environmental incidents.

Tailings and Waste Management

Tailings ponds and other waste containment systems present unique challenges for mining operations. Sediment sampling data helps teams assess whether these structures are functioning as intended by tracking leachate movement, identifying structural weaknesses, and detecting chemical changes in the surrounding environment.

Additionally, this information can guide decisions about classifying, treating, or repurposing waste material. For instance, if sediment samples from a tailings area show declining contaminant levels over a 12-month period, certain byproducts may be deemed safe for land application or alternative use. This reduces disposal costs and long-term liability. Alternatively, elevated levels of mercury or cyanide might indicate the need for additional containment or treatment measures.

Remediation and Site Closure

Sediment sampling plays a crucial role in closure planning as a mine approaches the end of its operational life. Data gathered during this phase helps to verify that cleanup efforts are effective and that disturbed areas have returned to acceptable environmental conditions.

Local regulators require this type of documentation as part of site decommissioning. Teams may collect sediment samples quarterly over a 12- to 24-month period to demonstrate that harmful substances are no longer migrating or accumulating beyond set limits. In some cases, sediment data is useful for modeling long-term stability scenarios, providing assurance that the site won’t pose future risks after closure.

Long-Term Monitoring Programs

Even after formal closure, mining sites may remain under observation for years—sometimes decades—depending on their location, legacy impacts, or historical contamination levels. Sediment sampling is a key component of these long-term monitoring efforts.

Data gathered from former drainage channels, tailings basins, or downgradient wetlands can reveal whether sediment remains stable or if new issues are emerging. In regions with seasonal flooding or freeze-thaw cycles, repeated measurements can also detect physical changes, such as increased erosion or sediment displacement, that might otherwise go unnoticed.

If conditions worsen, early detection gives regulators and property owners the chance to intervene before larger problems arise. Long-term monitoring also demonstrates accountability by showing that mining companies remain committed to environmental responsibility even after operations end.

Thoughtful Equipment Selection

Every phase of a mining project depends on trustworthy information, from exploration to closure; it’s how the mining industry uses sediment sampling data that turns raw material into actionable insight. When the data is consistent, timely, and detailed, it supports better environmental practices, regulatory alignment, and long-term site planning.

It’s important to have data that holds up under scrutiny. Trends need to be measurable, and shifts need to be attributable. When decisions carry financial or environmental weight, guesswork can’t be part of the equation. That level of confidence starts in the field. It depends on methods that are consistent, repeatable, and suited to the site.

We offer sludge and sediment sampling tools built for accuracy, durability, and reliability in the environments where mining teams work every day. Browse our selection online to find the right equipment for your projects, and experience the confidence that comes with dependable sampling every time.

Recent Posts

-

Soil Vapor Probe Installation Drive Tip Designs

Precision matters in soil vapor intrusion investigations. The quality of the data shapes risk assess …February 26, 2026 -

Bucket Auger Applications for High-Moisture Soils

Geotechnical and environmental sampling brings unpredictable field conditions, and saturated soils c …January 16, 2026 -

Why Sediment Sampling Is Important in Land Conservation

When it comes to land conservation, the decisions we make today shape the future of our natural spac …January 12, 2026